| Description: |

| √ Production speed is 40% higher than peers √ Replace the mould just 40 minutes √ One person can operate 4-6 sets of machines √ The yield more than 98% Passed the IS09001:2000 international standard certification |

| Brand: | YXH | Product: | stainless steel pipe production line | | Colour: | White/Green/Blue | Voltage: | 220/380/415/440V | | Useful time: | 40 years | Warranty Time: | 1 year |

After-Sales Service Provide: | Engineers available to service machinery overseas | | Usage: | Mainly to produces stainless steel pipes used for industrial area,such as air conditioner,auto exhaust,sanitary pipe appliance,sending liquid (oil,milk,beer) etc. |

| Type | Horizontal Shaft Dia(mm) | Vertical Shaft Dia(mm) | Material | Pipe Diameter(mm) | Pipe Thickness(mm) | Capacity (m/min) | Major Power (KW) | Installation Size (L*W)(m) | | ZG40 | 40 | 25 | ss,cs,etc | 8-50.8 | 0.5-2.0 | 1-5m/min | 7.5KW×1'+ 5.5KW×1' | 29×1.5 | | ZG50 | 50 | 30 | ss,cs,etc | 25.4-63.5 | 0.5-3.0 | 1-4m/min | 11W×1'+ 5.5KW×1' | 32×1.5 | | ZG60 | 60 | 40 | ss,cs,etc | 50.8-114 | 0.6-3.5 | 1-3m/min | 15KW×2' | 35×1.8 | | ZG80 | 80 | 50 | ss,cs,etc | 89-168 | 1.0-4.5 | 1-2.5m/min | 22KW×2' | 40×2.2 | | ZG100 | 100 | 60 | ss,cs,etc | 159-325 | 1.5-7.0 | 1-2.5m/min | 30KW×2' | 58×2.3 |

Automatic Production Process : Feeding--Forming--Welding--Leveling Inside Welding Line--Grindin Outside Welding Line--Solid Solution Treatment--Final Sizing--Straightening--ting--Unloading etc 1, Feeding ↓ |  | | Model | Basic parameter(mm) | Bear gravity(t) | Basic dimensions (mm) | | | a | b | c | | | | Single | 500 | 460-530 | 1000 | 3 | 1300*1500*1700 | | Double | 270 | 460-530 | 900 | 2 | 1600*1500*1700 |

Purpose:it is easy to use.It's indispensable for stainless steel pipe production line .u | 2, Forming ↓ |

Purpose:With the tempering high-frequency quenching fine grinding chrome plated. | 3, Welding ↓ |

Purpose:With 2 sets of squeezing rollers, and 500A Argon gas welding machine with single gun | 4, Leveling Inside Welding Line |

Purpose:With error output settign, start input and coupling of pipe production line,it is indispensable for production of senior industrial welded pipes. | 5, Grindin Outside Welding Line ↓ |

Purpose:With 3 pieces grinding head. Usage: to make the welding line more smooth. | 6, Solid Solution Treatment |  Purpose:With DSP digital control system, there are self production and self diagnosis functions.With small volume, it heats pipes rapidly and efficiently eith energy-saving and low-waste features. | 7, Final Sizing ↓ |

Purpose:For straightening purpose. | 8, Straig- htening ↓ |

Purpose:Turk-head section for straightening purpose. | 9, Cutting ↓ |

Purpose: It is easy to remove the sting of the pipe end, hydraulic driving to control up and down. It's the idea cutting tool. | 10, Unload- ing etc ↓ |

Purpose:Ease of installation and it's indispensable for stainless steel pipe production line . |

- The stainless steel pipe which made by stainless steel pipe production line can be used in these areas

- Application: air conditioner,auto exhaust,sanitary pipe appliance,sending liquid (oil,milk,beer) etc....

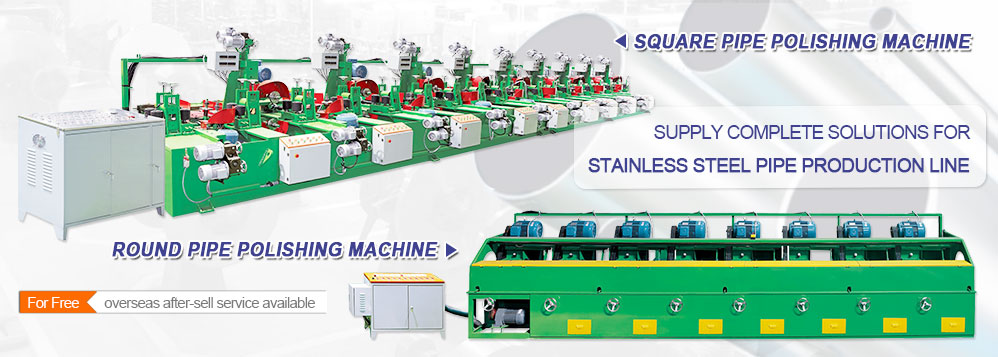

- As a professional manufacturer of the stainless steel pipe production line , Tube Mill, Mould/Roller, Pipe Polishing Machine , Slitting Machine,Embossing Machine,End Facing Machine etc, We have our standard type and we can also provide customized service and professional design based on your specific demands. Please feel to contact us for your requirements! We will try our best to satisfy your needs.

| | |

|

Pre-sale After- sale service We can: (1)Offer the welding technology for free. | (2)Help you train your staff. | (3)Offer plant designing and calculate power consumption. | (4)Send engineers to help you install the machines and train your staff online, until you can produce qualified pipes. | (5)Introduce the high-quality raw material supplier to you, and tell you how to distinguish good-quality raw materials from the bad. | (6)Special notice: The warranty period is one year, except man-damage. If you have any question in operation in operating the machines, you can call us or send emails, we will solve the problem for you asap. |

|

|